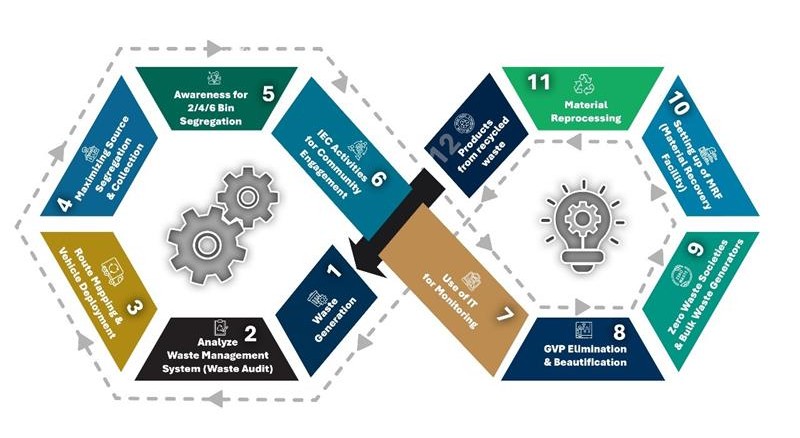

1. Analyze Waste Management System (Waste Audit)

A detailed assessment of the existing solid waste management system is the foundation of this model. This includes analyzing waste generation sources, types of waste (wet, dry, sanitary, hazardous), existing infrastructure, manpower, vehicle routes, citizen behavior, and compliance levels. The outcome guides all future interventions in a data-driven and customized manner.

2. Route Mapping & Vehicle Deployment

Based on audit results, a scientific route mapping plan is developed to ensure 100% coverage of all residential, commercial, institutional, and slum areas. Vehicles are deployed zone-wise, ensuring minimum fuel consumption, time efficiency, and maximum waste collection with route supervision and GPS monitoring in place.

3. Maximizing Source Segregation & Collection

This step focuses on increasing segregation efficiency at the source through focused IEC campaigns, colored bins (2/4/6 bin system), and daily monitoring. Door-to-door collection systems are redesigned to ensure segregated pick-up of wet, dry, and domestic hazardous waste, enabling smoother processing downstream.

4. Awareness for 2/4/6 Bin Segregation

Awareness drives and training sessions are organized for households, shopkeepers, street vendors, institutions, RWAs, and bulk waste generators to promote proper bin usage. The 2/4/6 bin model is explained practically to reduce mixing and improve material recovery and processing success rates.

5. IEC Activities for Community Engagement

Behavior change is the backbone of sustainable waste management. This step includes door-to-door awareness, street plays, nukkad nataks, wall art, school campaigns, and theme-based rallies aligned with Swachh Survekshan and SBM Toolkit indicators. IEC efforts are tailored based on ward-wise behavior mapping.

6. Use of IT for Monitoring

Modern IT tools such as GPS-based vehicle tracking, QR code scanning for waste pickup, MIS dashboards, citizen feedback apps, and Swachhata App integration are implemented to monitor field operations, track performance metrics, and ensure transparency and accountability.

7. GVP Elimination & Beautification

This step targets identification, elimination, and conversion of Garbage Vulnerable Points (GVPs) through behavioral interventions, enforcement, infrastructure (bins, fencing), regular sweeping, and community participation. Beautification includes mural painting, plantation, and converting hotspots into zero-dumping zones.

8. Zero Waste Societies & Bulk Waste Generators (BWGs)

RWAs and large institutions are sensitized and supported to become “Zero Waste” through onsite composting, dry waste sorting, and engagement in circular economy models. Bulk Waste Generators are tracked for rule compliance, encouraged to process wet waste at source, and penalized if non-compliant.

9. Setting up of MRF (Material Recovery Facility)

Establish decentralized or centralized Material Recovery Facilities to receive, sort, and process dry waste. Recyclables are baled and sold, reducing landfill dependency. MRFs are supported by trained manpower, vendor linkages, and record-keeping to ensure traceable material flow and economic sustainability.

10. Material Reprocessing

This final step closes the loop of the waste cycle by enabling reprocessing of recovered materials into new products. Partnerships are formed with recyclers, co-processors, compost buyers, and CBG units to repurpose segregated waste into value-added outputs, creating circular economy benefits.